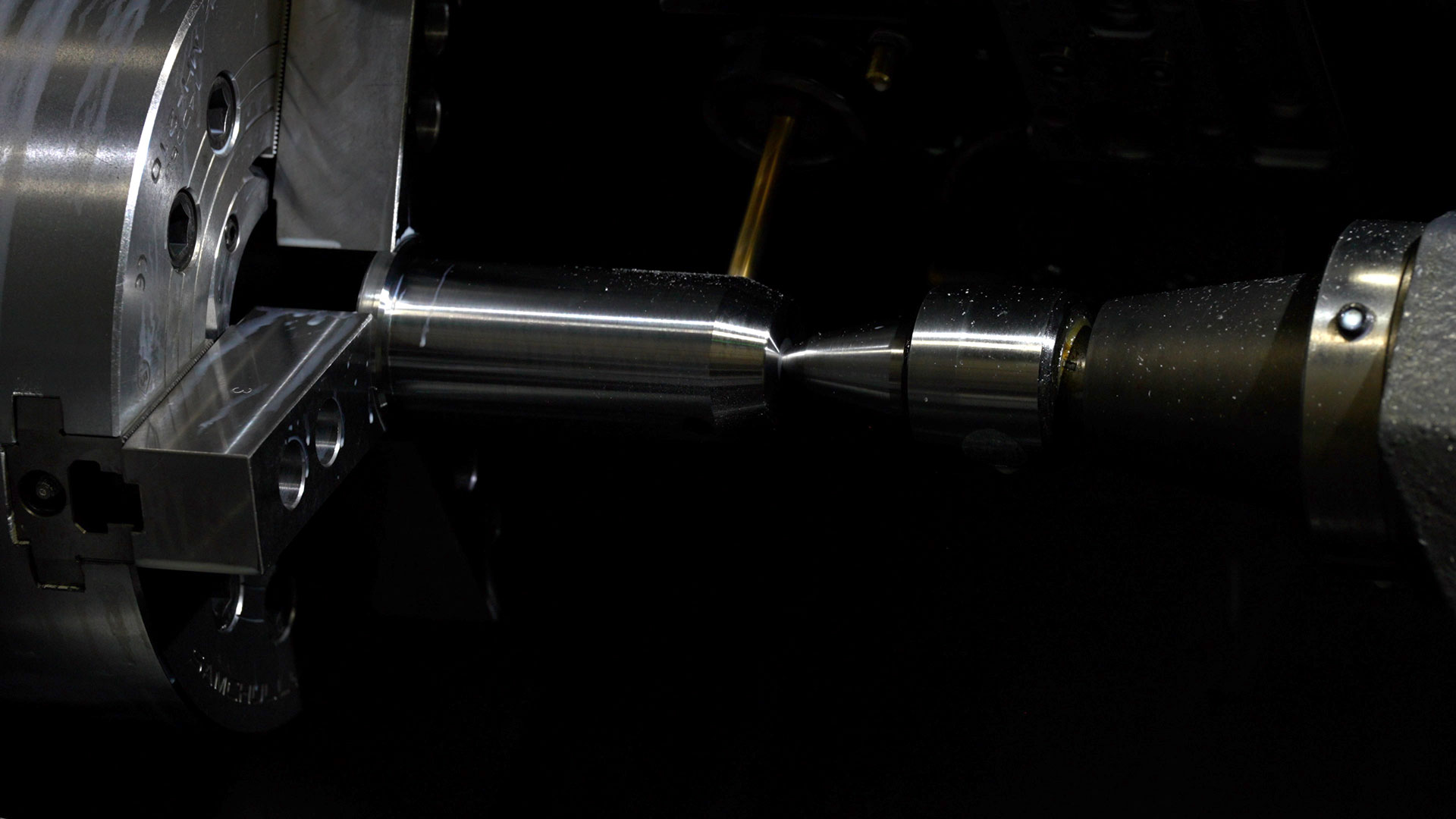

Machining & CNC Services

Our Computer Numerical Control (CNC) machining service harnesses the power of specialized tools and equipment to sculpt solid materials into intricate 3D shapes. By employing lathes and mills, we bring forth the remarkable possibilities to create custom metal components. This process is ideal for producing highly detailed and complex parts, prototypes, components, and custom products across various industries, including aerospace, automotive, electronics, and many more.

Craftsmanship & Process

Our machining capabilities provide a strategic edge, seamlessly integrating within our service variety. Using our Gibbs CAM, we blend technical expertise with creative finesse to program intricate parts. This step selects tooling, devising tool paths, and defining the machine's precise sequence to achieve the final product. Guided by this blend of science and art, our CNC programs play a pivotal role in ensuring the success of each component. With solid models or customer-supplied designs, we set up the machine with fixtures, jaws, and clamps, securing the raw material in a precise position. Our machine carefully executes the pre-determined program, while the feed rates and progress are closely monitored, which ensures a smooth operation that adheres to precision tolerances.

Equipment

- Gibbs CAM for programming

- Okuma Genos M560-V Mill

- Haas VF-3 Mill

- Haas ST30 SSY Lathe

- Haas ST28-LY Lathe

Materials

- Carbon Steel

- Aluminum

- Stainless Steel

- Bronze

- Specialty Alloys

Request a Quote

Shape your innovations with precision CNC machining. Contact us for custom 3D metal part creation.